串口屏模块

在工业过程设备领域,清晰可靠的液晶屏的重要性不言而喻。无论是监控关键参数、显示实时数据,还是实现用户交互,串口屏模块都发挥着至关重要的作用。本文将深入探讨使串口屏模块适用于工业过程设备的各个方面,包括其特点、优势及应用场景。

串口屏技术的发展

自问世以来,串口屏技术经历了长足发展。最初仅应用于计算器和数字手表,如今已扩展至制造、医疗、汽车等多元化行业。这一演进催生了专为工业环境设计的坚固耐用、高性能串口屏模块。

适用于恶劣环境的坚固结构

工业应用中,串口屏模块能否承受恶劣运行环境是关键考量因素。工业环境常伴随极端温度、高湿度、振动及冲击等严苛条件。因此,针对工业过程设备设计的串口屏模块采用坚固耐用的结构。其特点包括强化框架、耐用材料及先进密封技术,确保在严苛环境中稳定运行。

高可见度与清晰度

在工业环境中,操作人员需要快速准确地解读屏幕显示的信息,因此可见度和清晰度至关重要。工业级串口屏模块具备高亮度、宽视角及防眩光涂层,即使在强光或户外环境下也能确保良好的可见性。此外,先进显示技术可有效减少反射和失真,确保在不同光线条件下呈现清晰锐利的图像。

增强耐用性以延长使用寿命

在工业环境中,设备耐用性直接影响运营效率和维护成本。专为工业过程设备设计的串口屏模块经过严格测试,以确保长期可靠性。它们经过工程优化,可承受长时间使用,最大限度地降低像素退化、图像残留或其他形式的劣化风险。此外,这些模块还集成热管理系統和保护涂层,以提升耐用性并减少频繁更换的需要。

定制化满足特定需求

没有两个工业应用是完全相同的,显示解决方案的要求也可能大不相同。为了应对这种多样性,制造商提供可定制的串口屏模块,以满足特定应用需求。从不同屏幕尺寸和分辨率到专用触摸界面和通信协议,这些模块可以配置以满足精确要求,确保与现有系统无缝集成。

与物联网(IoT)和工业4.0的集成

随着物联网(IoT)和工业4.0的兴起,连接性已成为工业设备的关键考量因素。现代串口屏模块设计可无缝集成到网络系统中,实现实时数据交换、远程监控和预测性维护功能。通过利用物联网连接性,工业过程设备可优化性能、减少停机时间并提升整体运营效率。

符合行业标准

在安全关键的工业环境中,遵守行业标准和法规是不可或缺的。用于工业过程设备的串口屏模块需经过严格测试,以确保符合相关标准,如电气安全标准IEC 61010和环境保护标准NEMA等级。符合这些标准可确保产品质量、可靠性和安全性,为终端用户和监管机构提供信心。

在多元行业中的应用

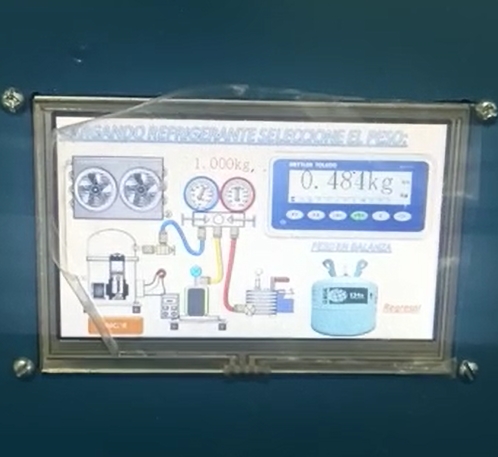

串口屏模块的通用性使其在工业过程设备领域中的广泛行业和应用中不可或缺。从制造工厂的控制面板和人机界面(HMI)系统,到能源发电设施和交通基础设施的监控液晶屏,凡是需要清晰、可靠且直观视觉界面的场合,串口屏模块均有应用。

未来趋势与创新

展望未来,串口屏技术的发展势头不减,驱动因素包括材料、制造工艺及显示技术的持续进步。新兴趋势如有机发光二极管(OLED)液晶屏、柔性基板及增强现实(AR)叠层技术,有望进一步提升串口屏模块在工业环境中的性能与适用性。通过紧跟这些技术发展并积极创新,工业过程设备可借助最新显示解决方案保持竞争力,并满足现代工业不断变化的需求。

结论

综上所述,串口屏模块是现代工业过程设备的核心组件,为监控、控制和交互提供关键的视觉界面。这些模块经过专门设计,具备耐用性、可视性和灵活性,能够满足工业环境的严苛要求。随着技术的持续进步和创新,串口屏技术将继续演进,为工业环境中的运营效率、安全性和用户体验带来新的可能性。